Zogulitsa

-

benchi lathe CZ1340A CZ1440A

*Zida zamabuleki zimatha kuyimitsa spindle mwachangu, koma mota siyiyima kuti itetezedwe bwino

* Supersonic pafupipafupi amawumitsa bedi njira;

* Zovala zodzigudubuza zolondola za spindle;

*Chitsulo chapamwamba kwambiri, pansi ndi magiya olimba mkati mwamutu;

* Ma gearbox osavuta komanso othamanga;

*Motor yamphamvu yokwanira;

*ASA D4 camlock spindle mphuno;

* Ntchito zosiyanasiyana zodulira ulusi zilipo -

Kubowola zazikulu zakuya ndi makina otopetsa, makina otopetsa a silinda T21100/T21160

T21100/T21160 mndandanda ndi zakuya-dzenje Machining makina, amene angathandize ndondomeko kubowola, wotopetsa ndi trepanning workpiece lalikulu ndi awiri lalikulu.Pamene akugwira ntchito, workpiece imazungulira pang'onopang'ono ndipo chida chodulira chimayenda mothamanga kwambiri ndi chakudya.Kuchotsa kwa chip cha BTA kumagwiritsidwa ntchito pomwe kubowola ndi kupititsa patsogolo tchipisi tachitsulo mkati mwa ndodo yoboola podula madzi ndikotopetsa.

-

Kubowola kwa Cylinder ndi makina otopetsa, Kubowola Kwakuya Ndi Makina Obowola T2180/T2280

T2180 ndi lalikulu yamphamvu pobowola ndi wotopetsa makina, amene angathe kugwira ntchito processing kubowola, wotopetsa ndi trepanning workpiece lalikulu ndi awiri lalikulu.Pamene akugwira ntchito, workpiece imazungulira pang'onopang'ono ndipo chida chodulira chimayenda mothamanga kwambiri ndi chakudya.Njira yochotsera chip ya BTA imagwiritsidwa ntchito pobowola ndi kupititsa patsogolo tchipisi tachitsulo mkati mwa ndodo yotopetsa podula madzi kuti asatope.

-

injini yopingasa lathe CW6163E,CW6180E,CW61100E,CE61200E

Bedi la lathe ndi lamtundu wofunikira pansi.Zimapangidwa mophatikizana.Pambuyo kuponyera ndi makina akhakula, ndi pansi pa ukalamba chithandizo kuonetsetsa structural rigidity makina onse.Njira yowongolera imayang'aniridwa ndi kuzimitsidwa pafupipafupi, kuuma sikochepera HRC52, kuuma kolimba sikuchepera 3mm, ndipo kukhazikika kwa makina onse ndikwabwino.

Mapangidwe omveka bwino amatsimikizira kuti lathe ili ndi kukhazikika kokwanira komanso kosasunthika.Ukadaulo wapamwamba umatsimikizira kuti makinawo ali ndi khalidwe labwino, phokoso lochepa komanso kugwedezeka kochepa.

Maonekedwe okongola, ophatikizidwa ndi mfundo za ergonomic, kusintha kosavuta kwa zogwirira ntchito, kugwira ntchito kosavuta komanso kukonza.

Zigawo zazikuluzikulu monga bedi, mutu, chonyamulira ndi tailstock zopangidwa ndi utomoni wapamwamba kwambiri wamchenga.Pambuyo pa kukalamba kwachilengedwe komanso kukalamba kochita kupanga, mbali zazikulu za makinawo zimatsimikiziridwa kuti zimakhala ndi ma deformation otsika komanso kukhazikika kwakukulu.

Spindle imatengera mawonekedwe atatu othandizira, okhala ndi kutalika koyenera, phokoso lochepa, kutentha kochepa komanso kusungidwa bwino.

Spindle ili ndi liwiro lalikulu, ntchito yokhazikika, kukwera kwa kutentha kochepa komanso kusungidwa bwino.

Zida zotumizira zazikulu zimakhala zowumitsidwa komanso pansi kuti zitsimikizire kulondola kwake, kugwira ntchito bwino komanso phokoso lochepa.

Mkulu kudula mphamvu ndi mkulu processing Mwachangu.

-

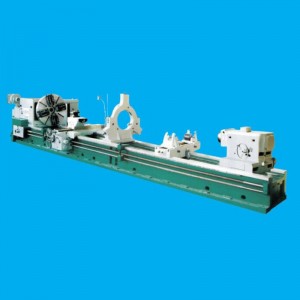

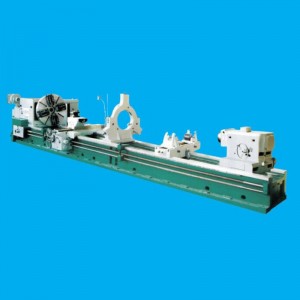

yopingasa injini lathe CWA61100-CWA61160

Chida ichi cha makina ndi lathe wamba wamba, womwe ndi woyenera kutembenuza bwalo lakunja, nkhope yomaliza, grooving, kudula, wotopetsa, kutembenuza dzenje lamkati, ulusi wokhotakhota ndi njira zina zamagawo a shaft, cylindrical ndi mbale mbali zamitundu yosiyanasiyana yokhala ndi zida zapamwamba- liwiro zitsulo ndi zida zolimba aloyi zitsulo.Spindle imatenga gawo lothandizira katatu, ndipo bedi limatenga bedi lofunika kwambiri, kuti bedi likhale lolimba kwambiri, ndipo apuloni, chida, ndi chishalo chikhoza kuyenda mofulumira.Chida cha makina ichi chili ndi ubwino wokhazikika mwamphamvu, kuchita bwino kwambiri, Otetezeka komanso odalirika, osavuta kugwiritsa ntchito komanso owoneka bwino.

-

yopingasa injini yachizolowezi lathe CW6163,CW6180(A),CW61100(A),CE61200(A)

Chida ichi ndi injini yapadziko lonse lapansi, yomwe ili yoyenera kutembenuza bwalo lakunja, nkhope yomaliza, grooving, kudula, kutopa, kutembenuza dzenje lamkati, ulusi wokhotakhota ndi njira zina zamagawo a shaft, cylindrical ndi mbale mbali za zinthu zosiyanasiyana zokhala ndi mkulu. - zitsulo zothamanga ndi zida zolimba za aloyi.Spindle imatenga gawo lothandizira katatu, ndipo bedi limatenga bedi lofunika kwambiri, kuti bedi likhale lolimba kwambiri, ndipo apuloni, chida, ndi chishalo chikhoza kuyenda mofulumira.Chida cha makina ichi chili ndi ubwino wokhazikika mwamphamvu, kuchita bwino kwambiri, Otetezeka komanso odalirika, osavuta kugwiritsa ntchito komanso owoneka bwino.

-

yopingasa injini ochiritsira lathe CW61128-CW611208

Mndandanda wa lathes wamba wa injini uwu ukhoza kugwira ntchito zosiyanasiyana zotembenuza.Itha kutembenuza bwalo lakunja, dzenje lamkati, nkhope yomaliza, ulusi wa metric, ulusi wa inchi, modulus ndi ulusi wa phula ndi mawonekedwe ena opangidwa ndi magawo osiyanasiyana.Chojambula chapamwamba chingagwiritsidwe ntchito kutembenuza ma tapers afupikitsa okha.Chojambula cham'mwambacho chingagwiritsidwenso ntchito kupanga makina a taper ataliatali pamene akufanana ndi chakudya chotalikirapo cha ngolo.Komanso akhoza kukwaniritsa ndondomeko zofunika pobowola, wotopetsa ndi trepanning.Ndiwoyeneranso kutembenuka kwamphamvu ndi zida za carbide, Kukonza zitsulo zosiyanasiyana zachitsulo komanso zopanda chitsulo.

-

yopingasa injini ochiritsira lathe CW61126-CW611206

Mndandanda wa makina ochiritsira wamba wakhala akusinthidwa mosalekeza ndi kusinthidwa ndi kampani yathu kwa zaka zoposa 40, pambuyo poyamwidwa ndi mapangidwe apamwamba ndi kupanga matekinoloje apanyumba ndi kunja, komanso pambuyo pogwiritsira ntchito ogwiritsa ntchito muzamlengalenga, njanji, valve ndi mafakitale ena, mchitidwe watsimikizira kuti lathes lalikulu yopingasa opangidwa ndi kampani yathu afika pa mlingo wapamwamba ku China.

The luso mbali mndandanda wa lathes ndi motere: choyamba, zigawo zikuluzikulu, spindle tailstock quill, etc. adutsa kukhathamiritsa kamangidwe ndi kukonza bwino, ndi mwatsatanetsatane mkulu ndi moyo;chachiwiri, zigawo zikuluzikulu, monga zitsulo za spindle ndi zigawo zikuluzikulu zamagetsi, zonse ndi zodziwika bwino kunyumba ndi kunja.

-

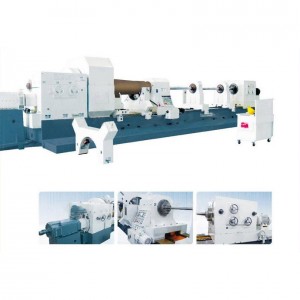

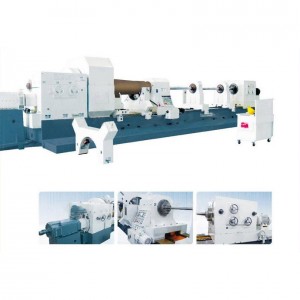

CNC chitoliro ulusi lathe, mafuta munda & dzenje spindle lathe QKD1325-1330-1335 mndandanda

Zida zamakinazi zimagwiritsidwa ntchito makamaka pokonza ulusi wa chitoliro, ndipo zimatha kudula ulusi wa metric ndi inchi cylindrical ndi conical chitoliro.Ndi oyenera pokonza chubu, casing, kubowola chitoliro, etc. mu mafuta, zitsulo, mankhwala, hydropower, geology ndi madipatimenti ena.

Zogwirizana ndi CNC system, yokhala ndi kuwongolera kwakukulu komanso kudalirika kwabwino.Chida cha makina chitha kutengera chowongolera cha PLC, chomwe chimapangitsa kudalirika ndikuwongolera kusinthasintha kwa chida cha makina.

-

CNC horizonta lathe makina SKQ61100 mndandanda

MODEL SKQ61100 SWING Φ1000mm SKQ61125 SWING Φ1250mm SKQ61140 SWING Φ1400mm SKQ61160 SWING Φ1600mm Zogwirizana ndi FANUC, SIEMENS kapena makina ena owongolera a CNC, ndi CRTm yowonetsera pulogalamu.AC servo motor imagwiritsidwa ntchito podyetsa nthawi yayitali komanso yodutsa, pulse encoder imagwiritsidwa ntchito poyankha.Njira yonse yolondolera bedi imapangidwa ndi chitsulo champhamvu kwambiri komanso pansi pambuyo pozimitsa ma audio pafupipafupi.Njira yolondolerapo bedi imayikidwa ndi pulasitiki, ndipo kugundana kumakhala kochepa.

-

Kubowola dzenje lakuya ndi makina otopetsa, kubowola kwa silinda ndi makina otopetsa, T21 mndandanda (T2110/T2120/T2136/T2225/T2236)

Makina awa ndi oyenera kubowola, kutayira ndi kugudubuza dzenje lapakati la magawo a shaft (hydraulic silinda, silinda ya mpweya, chitoliro chachitsulo, chida chobowola, etc.).Kubowola utenga BTA processing njira;PLC control system ndi touch screen;Chisindikizo chozungulira chamutu woponderezedwa wamafuta chimatengera mawonekedwe otsimikizira kutayikira kwamafuta omwe angopangidwa kumene, ndipo amatha kuyamwa bwino kugwedezeka kwa chida chodulira;Makina ozizira amakhala ndi thanki yamafuta pansi.

-

CNC kumapeto kwa nkhope yotembenuza lathe

CNC kumapeto kwa nkhope kutembenuza lathe, kudzera muulamuliro wodziwikiratu wa CNC system (FANUC/SIEMENS/GSK/KND, ndi zina), itha kugwiritsidwa ntchito potembenuza mitundu yosiyanasiyana ya dzenje lamkati, bwalo lakunja, pamwamba pa conical, pamwamba pa arc ndi ulusi.