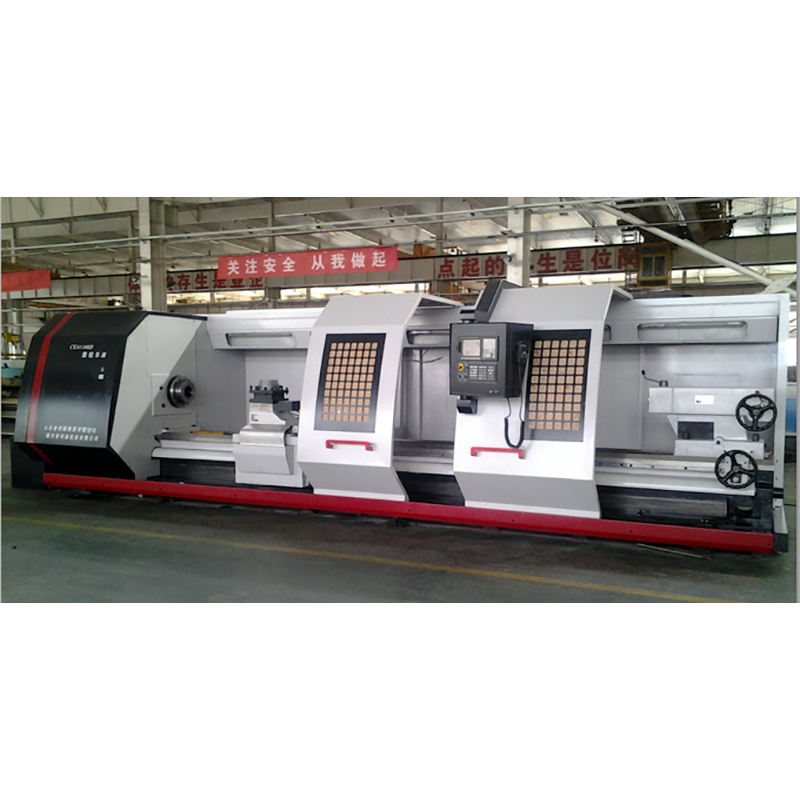

CH61200L CNC potembenukira pakati ndi C olamulira

Malangizo achidule

Makinawa amalumikizidwa ndi C axis, feed X ndi Z axis, ma axis atatu amatha kulumikizana ndikuyenda limodzi ndi ntchito zambiri komanso kudula kwambiri.

Zogwirizana ndi SIEMENS 828D CNC system.

Magiya awiri a liwiro la spindle, ndi liwiro lopanda masitepe mkati mwa magiya, kusintha kwa ma hydraulic gear, kudulidwa kwa mzere wosasinthasintha.Motor spindle yayikulu ndi SIEMENS 37KW AC servo motor, kuchepetsa liwiro ndikuwonjezera torque ndi magiya, liwiro la spindle ndi 5-200rpm.

C axis imayang'aniridwa ndi injini yolondola kwambiri ya AC servo, ndi kutseka kwa hydraulic automatic, ndikugwiritsa ntchito grating yozungulira pozindikira malo enieni;X axis imatengera SIEMENS AC servo mota yoyendetsedwa ndi liwiro lalitali kwambiri la mpira wononga kuti izindikire kusuntha kozungulira, olamulira a Z amatenga SIEMENS AC servo motor drive high precision worm reducer kuyenda motalika, onse a X, Z axis ali ndi grating kuti azindikire malo enieni, kutsekereza kuzungulira, ndi malo olondola bwino ndikubwereza kulondola kwa malo

kugwiritsa ntchito makina

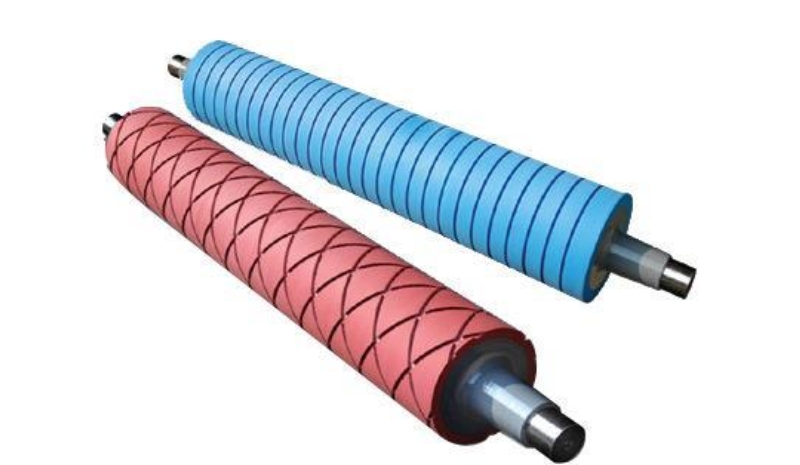

Awa ndi makina odula kwambiri, oyenera kudula chitsulo, chitsulo ndi chitsulo chosapanga dzimbiri ndi chitsulo chothamanga kwambiri komanso chida cholimba cha alloy.Kutha kukhala kutembenuza bwalo lakunja, nkhope yomaliza, kudula poyambira, kudula, kudula dzenje lamkati, mphero, mphero yozungulira, kubowola ndi kugogoda.

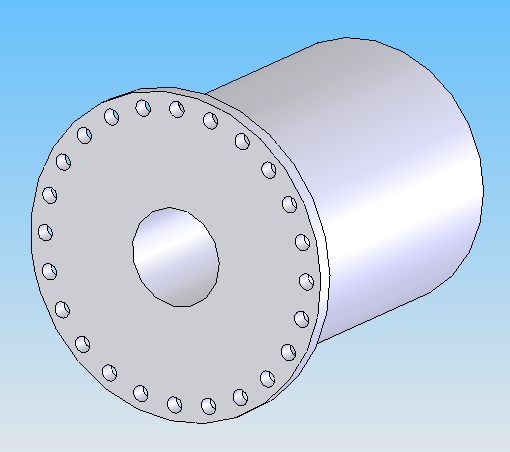

Sketch mapu a workpiece:

Njira yogayira

Kupukuta ulusi ndi kusintha phula

Milling spiral groove, mawonekedwe a sikelo

parameter ndi mphamvu

| Kukula kwa njira yowongolera | 1100 mm |

| Max.kuzungulira kwa bedi | φ2040 mm |

| Max.kusuntha m'mimba mwake pamwamba pa chida | φ1500 mm |

| Max.kutalika kwa workpiece | 12000 mm |

| Max.workpiece kulemera pakati pakati | 10T |

| kufala kwakukulu | |

| Kutsogolo kwa spindle | φ220 mm |

| Spindle range | 5-200r/mphindi |

| Diameter ya spindle | 130 mm |

| Mzere wakutsogolo wa bowo la spindle | metric No.140 |

| Main motor mphamvu, servo motor | 37kw pa |

| Spec.wa spindle end | 1:30 |

| kufalitsa chakudya | |

| Ulendo wa X axis | 85 mm |

| z ulendo wa axis | 11800 mm |

| x axis liwiro loyenda mwachangu | 4m/mphindi |

| z axis liwiro loyenda mwachangu | 4m/mphindi |

| Servo motor torque od x axis | 27 nm |

| Servo motor torque od z axis | 36 nm |

| Horizontal 8 position power turret | 0.5.473.532.8 |

| Chigawo kukula kwa chida shank | 32mmx32mm |

| Tailstock | |

| Quill diameter ya tailstock | φ260 mm |

| Kuyenda ulendo | 300 mm |

| Bowo la quill | metric No.80 |

| Mpumulo wokhazikika wothandizira (2 seti) | |

| Kutsekedwa kokhazikika kupuma | φ400-φ700mm |

| chuck | |

| Four nsagwada chuck | φ1600 mm |

| C axis | |

| Max.torque pansi pa clamped condition | 3000Nm |

| Kuyika kulondola kwa C axis | 36″ |

| Bweretsani kulondola kwa malo a C axis | 18″ |

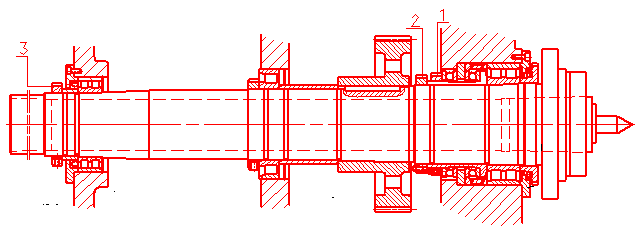

Main dongosolo

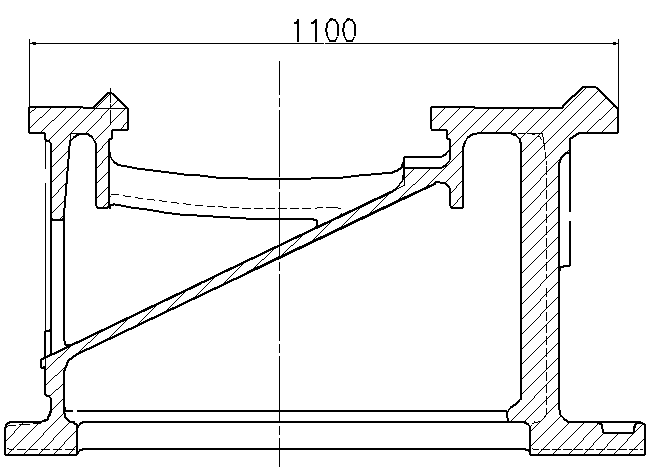

1)bedi

Bedi ndi bedi lamtundu wapansi wokhala ndi m'lifupi mwake 1100mm ndi kuponyera mchenga kwamphamvu kwambiri.Zinthu zake ndi HT300.Bedi lili ndi ubwino wa kuuma kwamphamvu, kunyamula kwakukulu ndi kukhazikika kwabwino

Njira yolondolera ndi phiri limodzi ndi mawonekedwe athyathyathya, kulimba kwa njira yolondolera kuli pamwamba pa HRC52, kuya kwakuya kolimba ndikothandiza kugwa.

Mkatikati mwa bedi la bedi amaperekedwa ndi nthiti yolimbitsa mawonekedwe a W, yomwe imalimbitsa kwambiri kulimba kwa bedi la makina ndikuchepetsa kusinthika chifukwa cha kulemera.

Pambuyo pa ukalamba wa kuponyedwa kwa bedi, kumatha kuchotsa kupsinjika kotsalira pakuponya, ndikuchepetsa kutulutsidwa kwa kupsinjika kotsalira pakukonza ndi kugwiritsa ntchito makinawo.

Pali mabowo otsetsereka komanso opindika kumbuyo kwa bedi omwe amagwiritsidwa ntchito pochotsa chip.Chip, zoziziritsa kukhosi, mafuta opaka mafuta ndi zina zotero zimachotsedwa mwachindunji mu tray ya chip.Chifukwa chake kuyeretsa kwa chip ndikosavuta, ndipo madzi ozizira amatha kubwezeretsedwanso

2) Mutu

Spindle imatenga chithandizo cha mfundo zitatu, ndi kutsogolo kutsogolo ngati mapeto okhazikika, pakati ndi kumbuyo kumathera ngati mapeto oyendayenda, kutsogolo ndi kumbuyo kumathera ngati chithandizo chachikulu, ndi chapakati ngati chothandizira chothandizira.Kuyika kwa axial kumayikidwa kumapeto kwa spindle, kotero kuti spindle imabwerera kumbuyo pambuyo potenthedwa, kuthetsa mphamvu ya kuwonjezereka kwa kutentha kwa spindle pa kulondola kwa chida cha makina.

Kuyendetsa kwakukulu kwa lathe kumazindikiridwa ndi Siemens AC spindle motor kudzera pa pulley ya lamba, zida ndi magawo anayi a hydraulic automatic shift.Ma torque okhazikika a spindle ndiakuluakulu ndipo kudula pafupipafupi kozungulira kumatha kuchitika.Chovala cha spindle ndi chotengera chapadera, cholondola kwambiri komanso cholimba champhamvu.

Mutuwo umathiridwa ndi mafuta amphamvu, ndipo magiya amutu ndi ma bere amathiridwa ndi pampu yapadera yamafuta.Kutsogolo kwa spindle kumatengera mawonekedwe osindikizira awiri a labyrinth ndi slot, omwe amatha kuletsa kutayikira kwamafuta ndi zinthu zakunja kuti zisalowe pamutu.

3): chida positi

Adopt German SAUTER 8 position horizontal turret 0.5.473.532.8, turret iyi ili ndi ntchito yodula bwalo lakunja, mapeto a nkhope ndi ulusi komanso mphero, kubowola ndi kugogoda.Turret iyi imayendetsedwa ndi SIEMENS servo motor yomwe idayikidwapo, ndikuphatikizidwa ndi zinthu zotsatirazi.

| Ser.Ayi. | Dzina | Mtundu | Qty |

| 1 | Mphamvu turret | 0.5.473.532.8 | 1 |

| 2 | Wodula mutu | 0.5.901.032/077790 | 1 |

| 3 | 0-degree mphamvu chodulira mphamvu | 0.5.921.106-117859 | 1 |

| 4 | 90-degree chodulira mphamvu | 0.5.921.206-117866 | 1 |

| 5 | Chomera chodulira chakunja chozungulira | B2-60X32X60-113908 | 2 |

| 6 | Mkati bwalo kudula chodulira chotchinga | E2-60X50-113961 | 2 |

4)Z ndi X axis:

Diameter of ball screw of X axis isφ40x5, Z axis imayendetsedwa ndi rack ndi giya, gawo la mano ndi m=5, ndi z axis imatenga kuwongolera kotseka kotseka ndi grating ya wolamulira.

5) Mchira wa mchira

Tailstock imakhala ndi gawo lakumtunda ndi gawo lapansi, bungwe losinthira quill ndi quill center limayikidwa kumtunda.Kuyenda kwa tailstock kumayendetsedwa ndi mota.Mtundu wa tailstock ukhoza kuzungulira.

6) dongosolo mafuta

Kupaka mafuta mu headstock, magiya ndi kubala mu headstock ndi zina zimaperekedwa ndi mpope wapadera, lubricating wa mayendedwe a mpira wononga ndi aliyense mafuta mfundo ya makina utenga intermittent ndi ndende kondomu, ndi nthawi kondomu ndi chosinthika, kotero kuti imalepheretsa kuwononga mafuta opaka mafuta, ndipo imatha kusintha makinawo momwe amayankhira komanso moyo wautumiki wa njira yowongolera ndi wononga mpira.

hydraulic system

Makina a Hydraulic amagwiritsidwa ntchito posintha liwiro la spindle ndikukakamiza kuziziritsa kwa magiya pamutu komanso loko ya C axis.

7) C olamulira

C axis imayendetsedwa ndi injini ya servo, imatha kusinthana ndi njira yotumizira ya spindle ndi C axis, kumbuyo kwa spindle kumakhala ndi ma grating apamwamba kwambiri ozungulira a C axis ndi ma brake damping mechanism.Ndi dongosolo lonse lotsekeka loyezera.

Kulondola kwa makina

| Malizitsani kudula bwalo lakunja | 0.005 mm |

| Machining kusasinthasintha, pa 300mm kutalika | 0.03 mm |

| Kuphwanyidwa kwa kumaliza kudula lathyathyathya, | |

| m'mimba mwake 300 mm | 0.025mm, concave |

| X axis | |

| malo olondola | X≤0.03mm |

| kubwereza kulondola kwa malo | X≤0.012mm |

| Z axis | |

| Positioning kulondola, pa 10000mm kutalika | X≤0.13mm |

| Bwerezani kulondola kwa malo | X≤0.05mm |

| C axis | |

| malo olondola | 36” |

| kubwereza kulondola kwa malo | 18” |